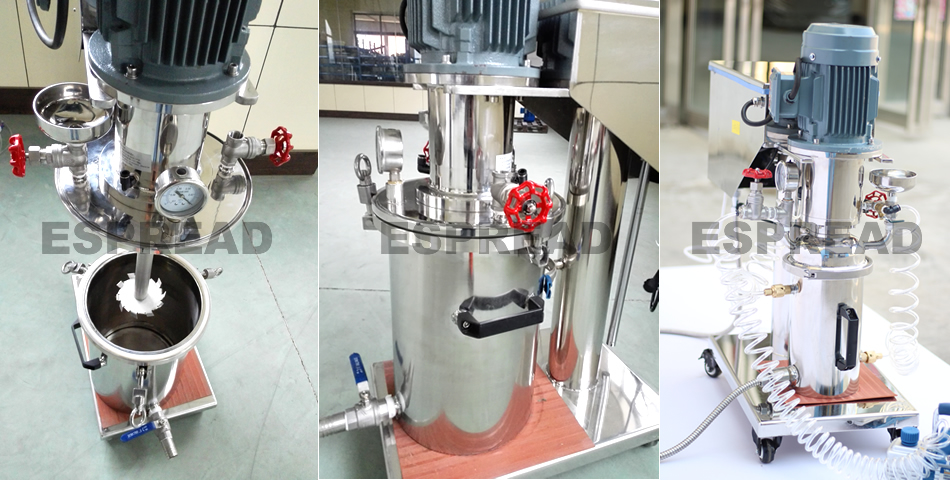

Product Introduction

Lab Closed Vacuum Disperser design for dispersing materials in vacuum tank. Material dispersed in vacuum tanks, it can decrease bubbles and volatilization of agents, expedite degassing and promote dispersing fineness.

Material viscosity: <=50,000 cps

Production Capacity: 0.6L-40L

Applied materials: Suitable for all kinds of materials with viscosity less than 50000cps, solids content less than 60%; such as emulsion paint, industrial paint, water-based ink, etc.

Working principle

Through the high-speed rotation dispersing disc, the material will become in annular form flow, resulting in strong vortex flow, which descend down to the bottom of the vortex in spiral state. During the process, materials are dispersed, dissolved, mixed and emulsified efficiently due to the strong shearing crash and friction among the particles, On the cylinder vacuum control Optional vacuum pump equipment,, high-speed mixing and physical vacuum defoaming at the same time, you can customize the constant temperature heating system.

Feature

Closed vacuum structure

Frequency Speed Control

Temperature and pressure control

Silence Electric lift up and down

Stainless steel frame machine body

| Model | Power | Speed | Capacity | Lifting way | Voltage |

| ESFSM-1.1 | 1.1kw | 0-3000rpm | 1L-5L | Manual /Electric | 220V/50Hz |

| ESFSM-2.2 | 2.2kw | 0-3000rpm | 5L-10L | Electric lifting | 220V/50Hz |

| ESFSM-4.0 | 4.0kw | 0-3000rpm | 10L-40L | Electric lifting | 220V/50Hz |

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales