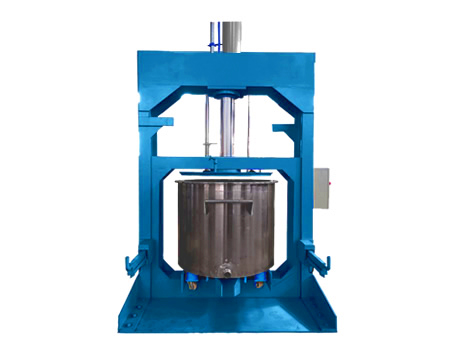

Product Introduction

Extruder machine is corollary equipment for planetary mixer or multi-function mixer, it is used to discharge or pack the mixed high viscosity material. It has single tank and double tanks form. By adopting torque motor control, it can deliver the high viscosity material such as ink, adhesive, silicone to the pipeline from the pressing plate or the bottom of the barrel through pressing plate, so that realize all kinds of pacing for different materials. The equipment can be barrel type and fixed type. Material viscosity: <=3,000,000 cps

Production Capacity: 100L-2.000L

Applied materials: Suitable for many kinds of vicious liquid chemicals such as paint and coatings, adhesives, agrochemicals, inks, putty, glues, sealants etc.

Working principle

It consists of baseboard, barrel positioning, hydraulic oil cylinders, beams, motor, gear pump, pressing plate, electric control cabinet etc. The hydraulic can be adjusted within the range of 0-20Mpa, the piston rod can stay in any position, and can work continuously under fixed and stable pressure; the seal ring of the pressing plate clinging to the inner wall of the tank (could customize with vacuum defoaming device) makes the material not coming out and no residue; the lifting support is hydraulically lifted to the top position, so that it's convenient for workers to pack. The extruder is characterized by its simple structure and convenient operation.

Product Advantages

Safe and Easy Operation

Adopt hydraulic cylinder as lifting actuators. Control the extruder up, stop, down though the valve, simple operation and high stability; with barrel holding device for fixing the mixing tank rapidly to prevent any possible accident due to tank displacement. Interlock between the tank in place and machine running can be set to avoid mal-operation.

Wide Application, High Efficiency

I can press the high viscosity material to next producing process within only a few minutes, the viscosity can be varied from ten thousand to millions cps; using couples of container and presser at the same time, the using efficiency increased greatly.

Clean Discharging

It equipped with seal ring which is matching the tank perfectly, during the pressing process, the seal ring cling to the wall of the tank tightly. No residue. Customized options

Different options are available such as explosion-proof type, closed type with scraper type, multi-function type, etc. Material can be customized to be SS321/SS316L or spraying treatment

| Model | Capacity(Liter) | Tank dia.(mm) | Lift distance(mm) | Hydraulic pump(kw) | Pressure(Tons) |

| ESEM-200 | 200 | 650 | 700 | 4 | 30 |

| ESEM-500 | 500 | 900 | 800 | 5.5 | 60 |

| ESEM-1000 | 1000 | 1100 | 1000 | 7.5 | 80 |

| ESEM-1500 | 1500 | 1300 | 1100 | 15 | 120 |

| Motor power can be adjustable based on liquid physical properties. | |||||

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales