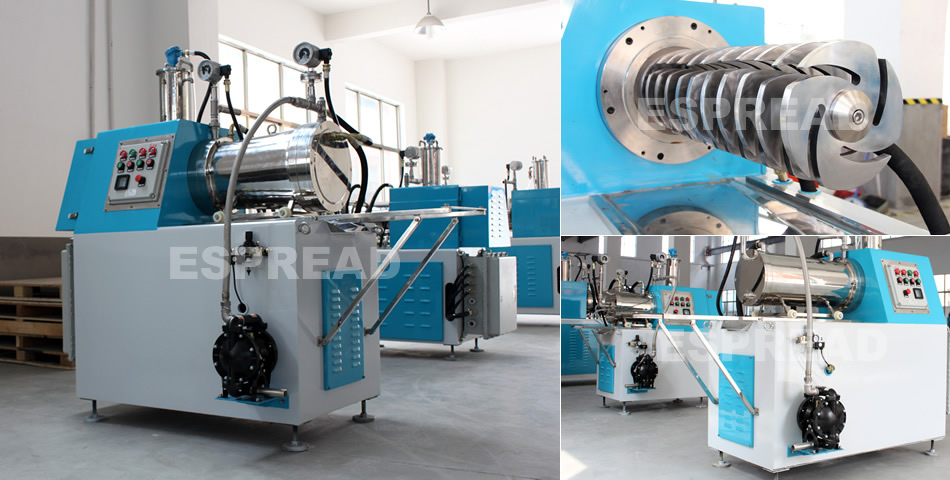

Product Introduction

ESWS Horizontal Bead Mill is a general wet grinding machine to reduce particle size for low and medium viscosity liquids, wide range of fineness grinding requirements of decorative paints, industrial coatings, general printing inks, and general pigment dispersions

Material Viscosity: <=50,000 cps

Production Capacity: 20-2,000L/hour

Application Fields: Suitable for dispersing, mixing materials in industries such as biology, pharmacy, food, paint, ink, adhesives, pigment, fertilizer etc.

Working principle

The delivery pump circulates the material from the tank to the grinding chamber. The disc drive the grinding beads and material to handle irregular movement and friction hardly, so the material can reduce particle size after milling when they passed through the separation screen.

Feature

The milling chamber is designed with cone shape, which makes the grinding medium to get high energy at the entry of materials feeding. Therefore, the liquid materials can be milled strongly from the beginning, and the milling result is much better than the straight-shape mills.

It is the single jacket cooling structure, but the designers reasonably deal with the relationship between the inner diameter of milling chamber, outer diameter of dispersing disc and the thickness of main shaft and speed of the shaft. Thus, the mill will work very efficient but not occurred high heat

The dynamic separation is made of powder alloy material, which has the advantages of self-cleaning, without blocking for high viscosity material and super anti-wearing resistance to make long lifetime for the mill.

ESWS series sand mill is used Burgmann from German for its mechanical seal. The surfaces of dynamic or static rings are both made from carbonized Silicon. And the O-ring is made of Teflon, which can bear the corrosion caused by strong solvent.

| Model | Power(kw) | Speed(m/s) | Chamber size(L) | Capacity(L/hour) | Beads size(mm) |

| ESWS-5 | 5.5 | 10 | 5 | 20-200 | 1.4-1.6 |

| ESWS-20 | 18.5 | 10 | 20 | 100-800 | 1.4-1.6 |

| ESWS-30 | 22 | 10 | 30 | 100-1000 | 1.4-1.6 |

| ESWS-50 | 30 | 10 | 50 | 200-1500 | 1.4-1.6 |

| ESWS-60 | 37 | 10 | 60 | 200-2000 | 1.4-1.6 |

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales