Product Introduction

ESN type of horizontal bead mill is an high efficiency wet process grinding machine to reduce particle size to nanometer ranges for low and medium viscosity range, wide range of fineness grinding requirements of paints, coatings, inks, pigment dispersion and others.

Material Viscosity: <=20,000 cps

Production Capacity: 1-2,000L/hour

Application Fields: Suitable for ceramic ink, colorants, lithium battery pastes, thermal paper pulp, electronic slurry, Nano pigment etc.

Working principle

The delivery pump circulates the material from the tank to the grinding chamber. The disc drive the grinding beads and material to handle irregular movement and friction hardly, so the material can be reduced particle size after milling when they passed through the separation screen.

Feature

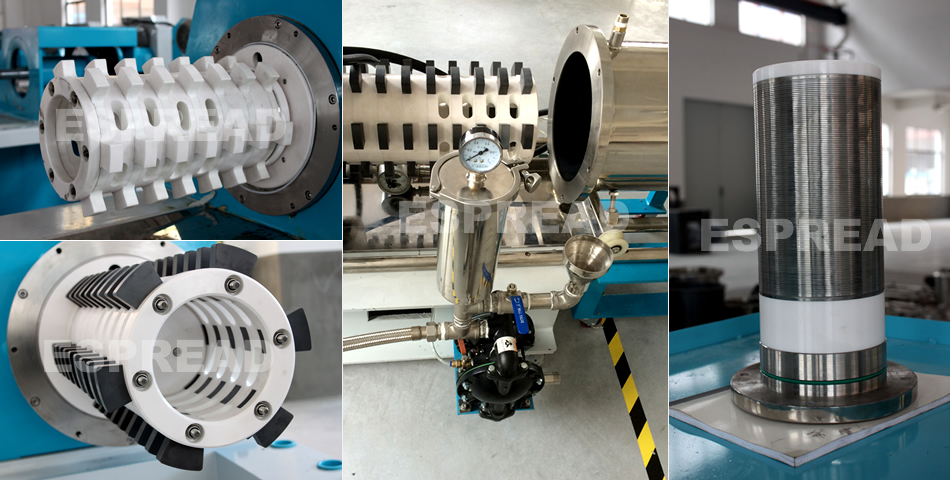

Adopt integrated double end mechanical seals, individual lubrication system for the sealing oil by gear pump

Adopt turbo static centrifugal separation system, and minimum use 0,1mm beads.

Special designed cooling system not for the stators of the chamber but for material discharging area.

Static separation screen is made of SS304, and the gap can be designed suitable for 0.1mm beads operation, the separation is turbo static centrifugal system.

Rotor material use Zirconium Oxide, hard alloy and inside grinding chamber is made of SiC and outside chamber is made of SS304.

Minimum 0.1mm diameter zirconium beads can be used

High quality PTFE diaphragm pump is included

| Model | Power(kw) | Speed(m/s) | Chamber size(L) | Capacity(L/hour) | Beads size(mm) |

| ESN-0.5 | 2.2 | 12 | 0.5 | 1-5 | 0.1-1.0 |

| ESN-6 | 15 | 14 | 6 | 20-200 | 0.1-1.0 |

| ESN-10 | 22 | 14 | 10 | 30-300 | 0.1-1.0 |

| ESN-30 | 45 | 14 | 30 | 100-1000 | 0.1-1.0 |

| ESN-60 | 75 | 14 | 60 | 200-2000 | 0.1-1.0 |

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales