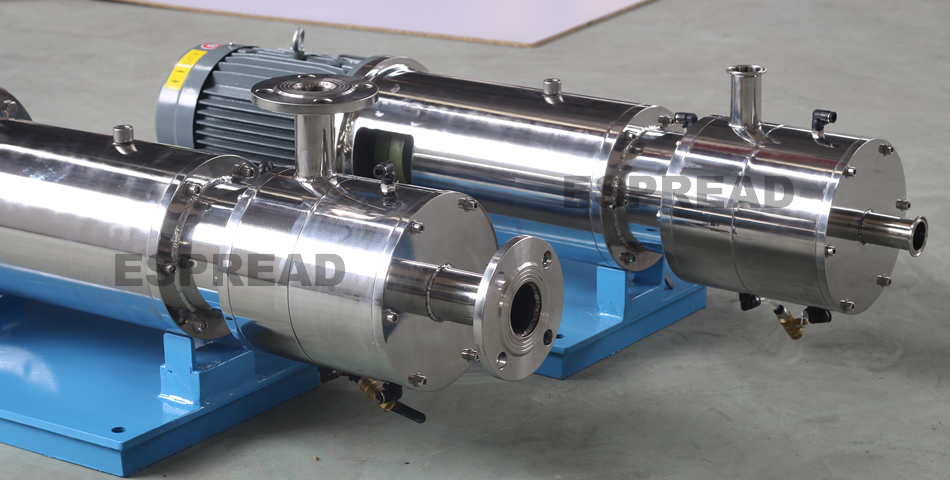

Product Introduction

Single stage Inline High Shear Mixer is a continuous production type emulsifier with high efficiency. It processed materials in continuous production or circulation of fine materials. The motor drives the rotor to rotate at high speed. Suitable for less than 10000cps high viscosity fluids low emulsification and homogenization, such as aqueous oil-based ink, industrial paint and wood, all kinds of pastes, pesticide suspensions, asphalt, fruit jam, pulp, lubricants, creams, lipsticks, milk products, textile.

Material viscosity: <=10,000 cps

Production Capacity: 1000L-80000L/hour

Applied materials: suitable for emulsifying, homogenizing and dispersing materials in industries, such as biology, pharmacy, food, cosmetic, ink and pesticides etc.

Feature

Capacity

Self-pumping throughputs of 1000 to 80,000 litres/hr.

No Bypassing

Product cannot bypass the precision rotor/stator workhead.

Interchangeable Workheads

Three stages rotor/stator configurations workheads as standard. For the rotor/stators configurations, 2,4 and 6 layers structures makes the best shearing result.

Materials of Construction

Product contact in SS304 or 316L stainless steel.

Motor Specification

Standard and explosion proof motors (Siemens ,ABB etc) are available as standard.

Inlet and Outlet Connections

All sanitary screw or flange fittings available on request (e.g. ISS, D/N, RJT, SMS, Tri-clamp, etc.).

Sealing

Single or double mechanical shaft seals available as standard.

Cooling

Cooling jacket structure as standard

| Model | Power(KW) | Speed(RPM) | Flow rate(m3/h) | Outlet(mm) | Inlet(mm) | Weight(kg) |

| ESSW3-4 | 4 | 3000 | 2.5 | DN32 | DN40 | 225 |

| ESSW3-7.5 | 7.5 | 3000 | 6 | DN40 | DN50 | 270 |

| ESSW3-11 | 11 | 3000 | 11 | DN50 | DN65 | 325 |

| ESSW3-15 | 15 | 3000 | 16 | DN50 | DN65 | 360 |

| ESSW3-18.5 | 18.5 | 3000 | 20 | DN65 | DN80 | 395 |

| ESSW3-22 | 22 | 3000 | 25 | DN65 | DN80 | 420 |

| ESSW3-30 | 30 | 3000 | 32 | DN80 | DN100 | 480 |

| ESSW3-37 | 37 | 3000 | 40 | DN80 | DN100 | 570 |

| ESSW3-45 | 45 | 3000 | 50 | DN100 | DN125 | 660 |

| ESSW3-75 | 75 | 3000 | 60 | DN125 | DN150 | 225 |

1. discuss full requirement with our sales engineers

2. sending official quotation based on requirements

3. order confirmation mutually

4. arrange deposit payment according to the order

5. arrange production at our factory

6. arrange the final payment

7. arrange shipping and logistics

8. machine received confirmation

9. installation and commissioning if needed

10. order complete and aftersales